Absolute3D provides high-accuracy 3D laser scanning, reverse-engineering, inspection, and product design services for engineering teams and manufacturers across Australia. We capture precise measurement data, reconstruct clean CAD models, and deliver engineering-grade outputs suitable for machining, molding, fabrication, and production workflows.

Whether you’re replicating an existing component, validating tooling, or developing a new product, we deliver reliable results with ISO-certified accuracy, fast turnaround times, and clear technical communication. Our goal is to support your engineering process with precise data and dependable deliverables.

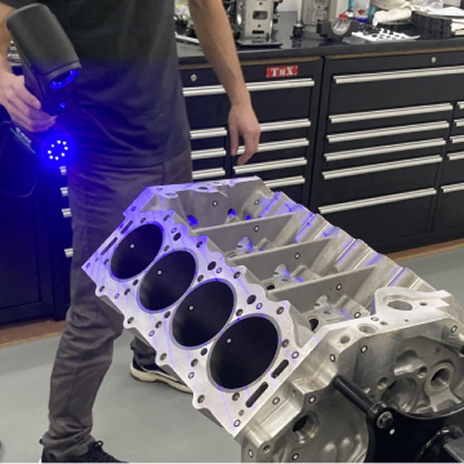

Portable, mobile on-site scanning We can scan components, assemblies, machinery, or vehicles directly at your location—minimising downtime.

ISO-Certified, Traceable Accuracy Our 3D scanners are calibrated by an ISO 17025–accredited laboratory, delivering metrology-grade accuracy with traceable measurement confidence.

Manufacturing-ready CAD Clean parametric CAD models prepared for machining, molding, fabrication, or production workflows, delivered in STEP, IGES, STL, or any required format.

Faster development cycles Fast scanning, efficient modelling, and a streamlined workflow help reduce engineering time, shorten manufacturing lead times, and integrate smoothly into your existing CAD or PLM systems.

We offer services centred around high-accuracy 3D laser scanning and reverse engineering. These core capabilities allow us to capture physical parts and convert them into clean, editable CAD models ready for redesign, documentation, or manufacturing.

For projects requiring further development, we provide product design and engineering consulting to guide you through the entire product development process. We also offer inspection reporting to verify that parts meet specified tolerances before production begins.

When you’re ready to manufacture, our vetted network of trusted partners can support tooling and production, ensuring your design is delivered reliably, efficiently, and to specification.

Tell us about your projectSend photos, part dimensions, or a brief outline of what you need.

We complete the scanWe can scan parts onsite or at our studio. High-resolution data is captured quickly.

CAD modelling or inspectionDepending on your goal, we produce accurate CAD files or inspection reports.

Receive your deliverablesYou’ll get accurate scan data, clean CAD models, and analysis reports to support your workflow.

If you have questions please feel free to contact us.